2014

A Vision Begins

Every great journey begins with a vision.

For Wisdom Vision Optical, that vision started in 2014, in a small workshop in Shenzhen. With less than a dozen dedicated craftsmen and a space of only a few hundred square meters, we set out with a simple yet ambitious goal: to create eyewear that combined artistry, precision, and enduring quality.

The early years were not easy, but our passion and craftsmanship soon earned the trust of clients from Europe and North America.

Begins

It was a step that transformed us from a local manufacturer into a global collaborator.

2018

A New Era of Growth

By 2018, our persistence bore fruit. We moved into a new, modern 5,000㎡ facility, equipped with advanced machinery and multiple production lines, where over one hundred skilled professionals now craft more than 150,000 pairs of eyewear each month. This expansion gave us the strength to serve both leading global brands and niche, high-end projects with the same level of care and precision.

2020

Defining the Future

In 2020, we defined a long-term vision built on three pillars:

Global e-commerce, connecting directly with consumers around the world.

Traditional craftsmanship, strengthening our role as a trusted manufacturing partner.

Brand building, creating lasting value through design, innovation, and storytelling.

Today

From a small workshop to a trusted international manufacturer, Wisdom Vision Optical has grown, but our spirit remains the same. Every frame we produce carries not only craftsmanship but also our values: dedication, precision, and integrity.

Together with our global partners, our story continues.

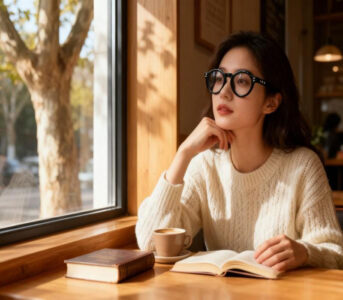

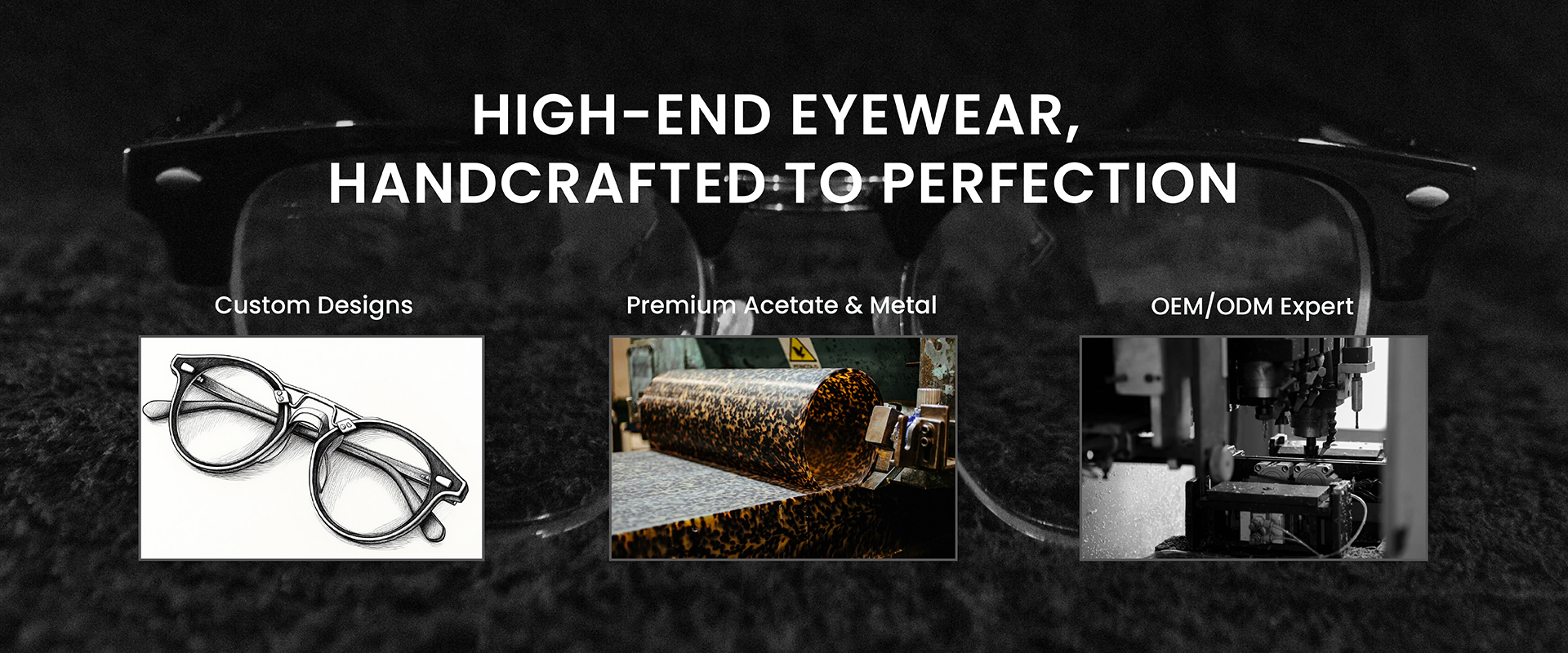

Our Craft

At Wisdom Vision Optical, every frame goes through a journey of care.

From material selection to hand-polishing, from precise assembly to final inspection, we treat each step with patience and responsibility.

It’s not just about making eyewear—it’s about ensuring comfort, durability, and trust for everyone who wears it.

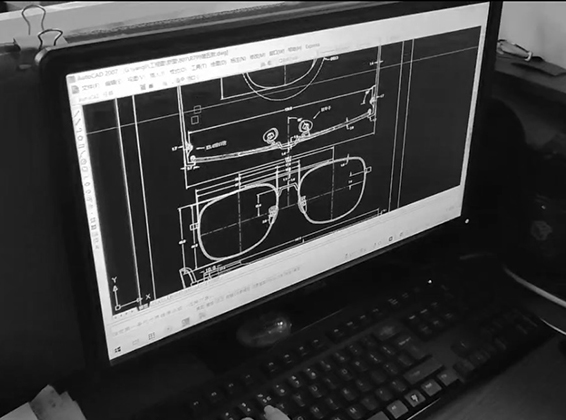

Engineering

Design,drawings and artwork procedures settings before sampling or production

Stamping

High quality raw parts supply , metal front, temple, trims, bridge with various pattern requirements processing

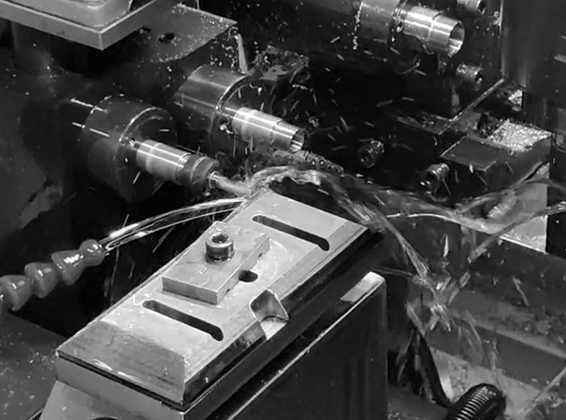

Milling

Accurancy work for raw metal accessories

Molding

High accurate metal parts performance assurance

CNC

Advanced Auto acetat front process, it is less labor but with high efficiency and accurancy performance

Temple Shooting

Metal core shooting for acetate temple or tips prodcuing

Engraving

Details work for logos or trims in finished products

Hinge inseration

Hinges inseration for temple and front

Tumbling

Three rounds process for a gloss surface at the finished with different mixture stuff in each round

Manual Polishing

Necessary procedure to assue finished shiny request

Auto Lens Cutting Centre

Demo lens, sunlens, reading lens well cutting base

Assembling

For screws, parts, front and temple assembling workshop

Packing

Finshed frame for packages and to warehouse for delivery preparation

Our Vision

When we started Wisdom Vision Optical in 2014, our dream was simple:

To bring high-quality eyewear to the world, and to bring the world closer through trade.Our vision has never changed. We aim to be a leader in the global eyewear trade, connecting cultures and markets. For us, “buy globally, sell globally” is not just a slogan—it is our way of building bridges between people, brands, and ideas.Every frame we make carries this belief: that good products know no borders.And every partnership we build reflects our promise: to treat each client as a trusted friend, and each collaboration as a shared journey.

This is the story we continue to write—together with you.